In today’s post, we’ll delve deeper into what various physical and chemical treatments are involved in beef processing, and how they helped the beef that we know of today came to be.

Meat from bovines is what we commonly refer to as beef. It is an excellent source of vitamin B12, protein, zinc, and selenium, which are essential nutrients for humans.

Additionally, beef is also chock-full of vitamin B6, riboflavin, iron, niacin, and phosphorus. Interesting tidbit: the delicious and nutritious beef you can eat for dinner is the result of multiple stages of beef processing methods.

Beef Processing Stages

Slaughter

The meat processing starts in the slaughter stage. Before conducting the slaughter, a professional meat inspector examines the animal and makes sure it is qualified for human consumption. Once the animal passes the health check, it will be passed on to a slaughterhouse.

The process includes three stages: pre-slaughter handling, stunning, and slaughtering. The United States Humane Slaughter Act requires the humane treatment of the animals at all of these stages.

Additionally, the United States Department of Agriculture (USDA) has set forth food safety guidelines that every facility must comply.

From animal welfare to food safety and handling, USDA inspectors must oversee each stage. Trusted and professional slaughter facilities will also go above and beyond to ensure that those guidelines are met.

Aging

The second step in beef processing is the aging stage. The beef is hung in a large cooler for 9 to 14 days; for lamb, it’s 7 to 14 days, and pork is 4 to 10 days. However, the actual time for the meat aging process will depend on the performance and quality of the cooler used and the overall condition of the meat upon harvesting.

This step will improve the flavor and texture of the meat. The aging allows the enzymes to break down making the meat more tender.

Electrical stimulation can also be used to accelerate the meat aging process. ES entails speeding up the average decrease of pH onset after the death of the animal by using 504 volts at three amps.

If ES is applied immediately after stunning the animal, it can be utilized at a lower voltage. If it’s delayed for an hour or more after stunning, up to 1,600 volts is needed to start ES.

ES is mainly used on lamb to develop the tenderization stage and protect the meat from cold reduction, which means cooling too quickly that it prevents the rigor resolution stage to take place. It is used to start up the rigor peak stage to reach the resolution stage. This step improves the tenderness of the meat and contributes to the bright red color.

Cutting and Packaging

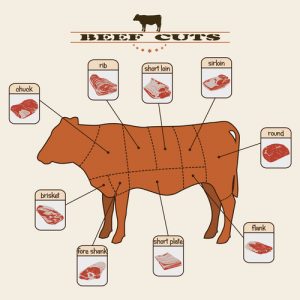

The next stage in beef processing is the cutting and packaging. An industrial processor can cut the beef according to the end beef products. Additionally, the cuts can be handled in multiple ways such as ground for sausage and burger patties, salting, pickling, etc.

Additionally, beef cuts can be turned into short ribs, tenderloins, briskets, roasts, steaks, or even processed as jerky, deli meats, corned beef, and other processed meat products.

A huge processing facility typically employs hundred of butchers to expertly and quickly carve out the meat. The process also involves an accurate tracking system that traces every piece of meat back to a specific animal.

Strict Standards and Regulations

The beef processing industry has often been the subject of scrutiny from the media and other concerned groups. From animal welfare to hygiene standards, processing methods to product labeling and formation, the meat industry has attracted a lot of criticisms. Enforcing strict and recognized rules and guidelines by third-party auditors are the key to maintaining consumer trust and confidence. There is a considerable amount of standards and regulations governing the production of meat products.

Beef processing standards have to categories: generic and product specific. Generic, as the name applies, is used by all sectors of the food industry worldwide. On the other hand, product specific standards are those that only can be applied to particular products.

Additionally, beef and meat processors follow and implement standards and guidelines for many reasons, such as:

- Processors can have the confidence in their production facilities, methods applied, and in-house management system when rules are followed.

- They can also use a verification or make a substantial claim about their products

- These verifications can support a due diligence defense.

- As a condition of supply, meat retailers may also specify that to supply and make their own label, an inspection of the beef processing procedures must take place.